The complete range of Cleanroom Intralogistics

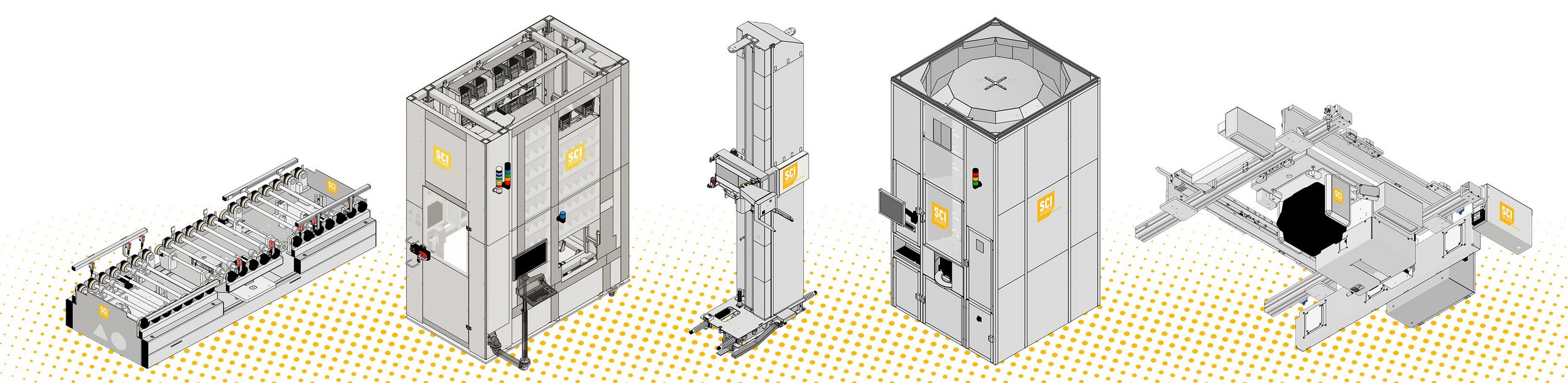

Warehouse systems

Storage and retrieval machines

Customer-specific grippers and racks (maximum packaging with double depth)

Special solutions for wafer packaging (N2 purging)

Transfer stations

- Manual, partially automated, and fully automated solutions

- FOUP handling: Docking station, transfer to sorter and load ports

Transport Systems

Linear Hoist System

Overhead conveyor system with passive transport route and cleanroom-optimised lowering shuttle

Lift stations across multiple stories

Conveyor systems up to ISO class 3

Software and quality assurance

Control and monitoring systems, warehouse management/databases, visualisation

Remote maintenance, diagnostics, and reporting

Flexible interface design and support for numerous protocols (e.g. SECS/GEM)