Features

- Storage of different transport containers (FOUP, FOSB)

- Fulfils ISO class 5 cleanroom class

- IO-ports:

- Manual I/O ports (rotary gate)

- Automatic I/O ports (OHT connection)

- Connection to equipment possible

- Dockingstation for transport trolley / cart

- SEMI-E88 MCS interface

- SEMI-E84 transfer interface

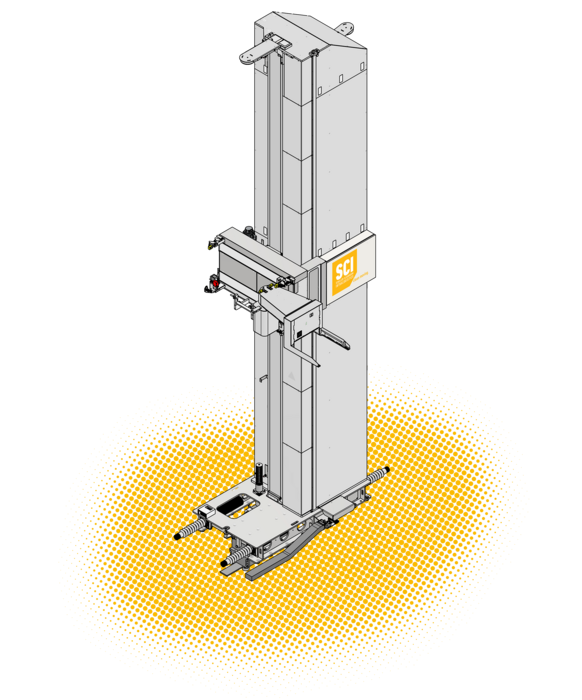

Technical data

- Medium cycle time: 20 - 25 sec.

- Dimensions:

- Height: 6,1 m

- Width: 2,75 m

- Length: Max 47 m

- SIEMENS S7 PLC

Datasheet

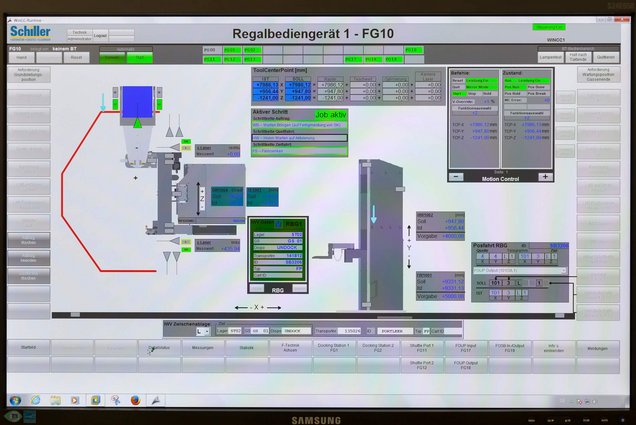

Software

- Remote access: Web front-end including user administration

- Data tracking: Material tracking, system counter visualisation

- SECS interface: SEMI E88-conformant interface, expandable upon request by the customer

- Interfaces:

- Web frontend via http Port 80

- SECS/GEM Ethernet interface

- Ethernet interface to the PLC systems

- Inventory function

- Optional 3D inventory visualisation

Warehouse management system

SWarePro