Features

- Transport of different containers (FOUP or FOSB with top flange, HA 200)

- Fulfils ISO class 3 cleanroom class

- SEMI-E153 MCS interface

- SEMI-E84 transfer interface

Technical data

- Speed: depends on project and carrier types

- SIEMENS TIA PLC

- Grabber:

- Active grabber for boxes with top flange

- Lateral clamping (form fit)

- Top flange rotary gripper

Advantages

- Fast delivery of the containers to equipment

- Non-railbound like shuttle systems

- Integration of a ceiling-mounted warehouse possible

Control system

SHostPro

Datasheet

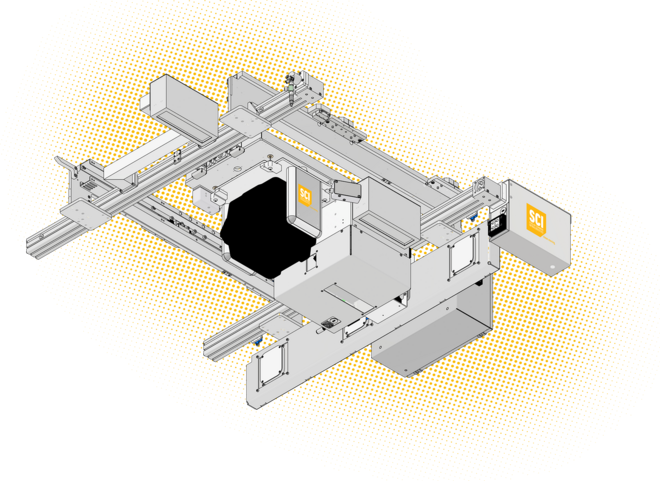

OHT (Overhead hoist transfer) Shuttle

The SCI OHT system is a powerful and elegant solution for fab overhead transport applications. It’s flexibility also enables the retrofit and extension of existing automation systems.

The Shuttle system features exclusively passive track elements and follows strict design principles of particle avoidance in order to meet the challenges of state-of-the-art cleanroom manufacturing environment.