Features

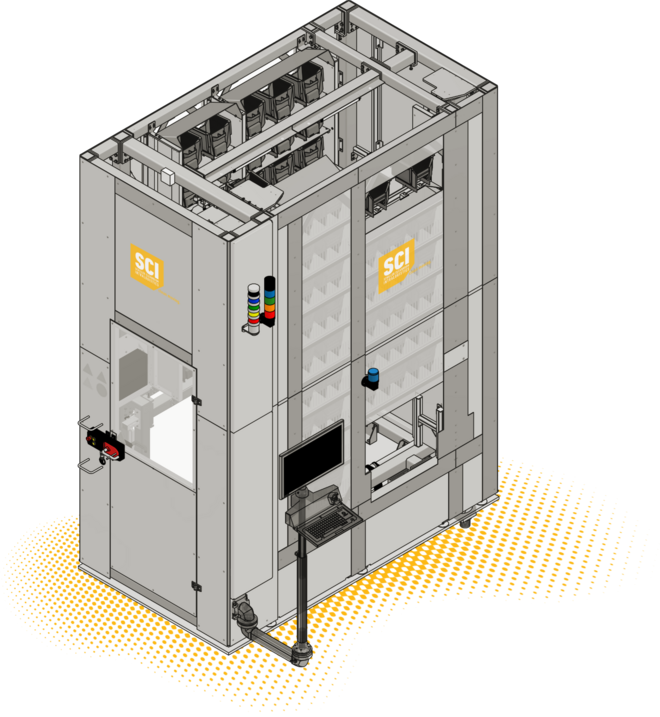

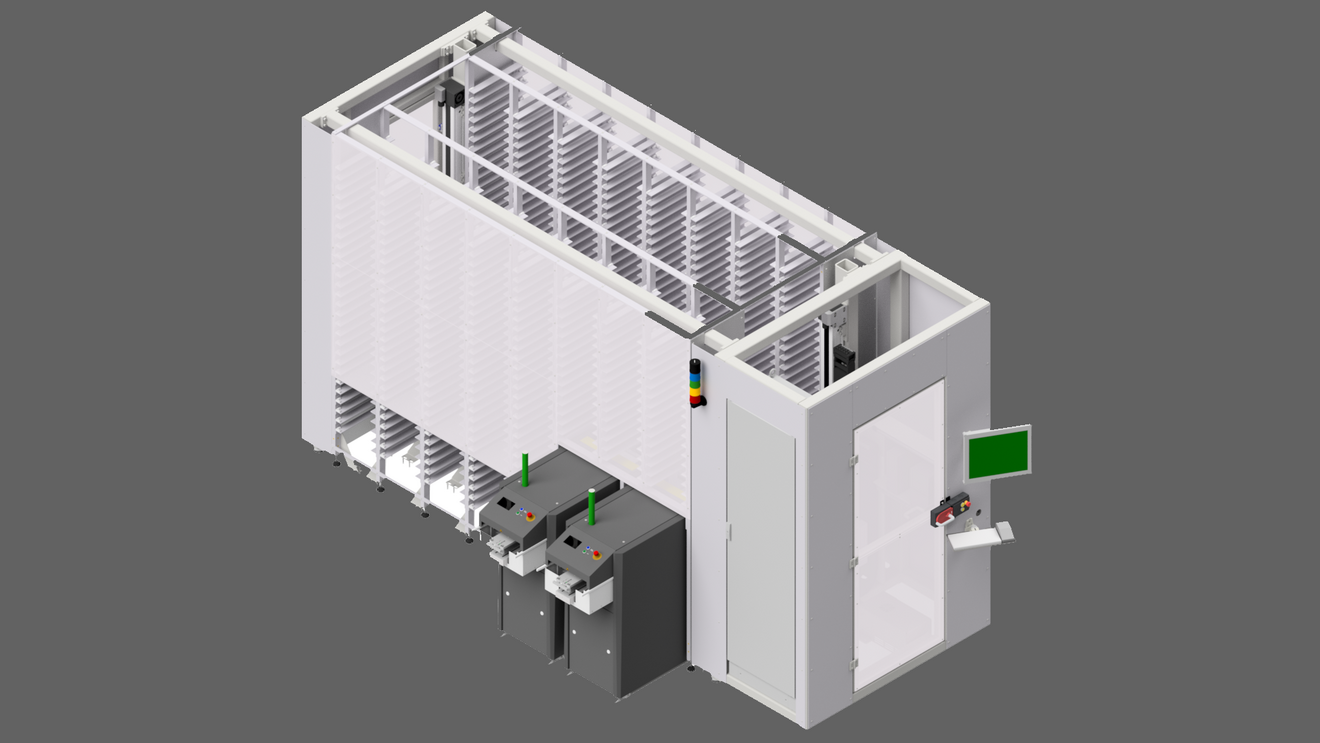

- Storage of different transport containers (HA200, OC, FOUP, FOSB, Other)

- Fulfils ISO class 4 / 3 cleanroom class

- IO-ports:

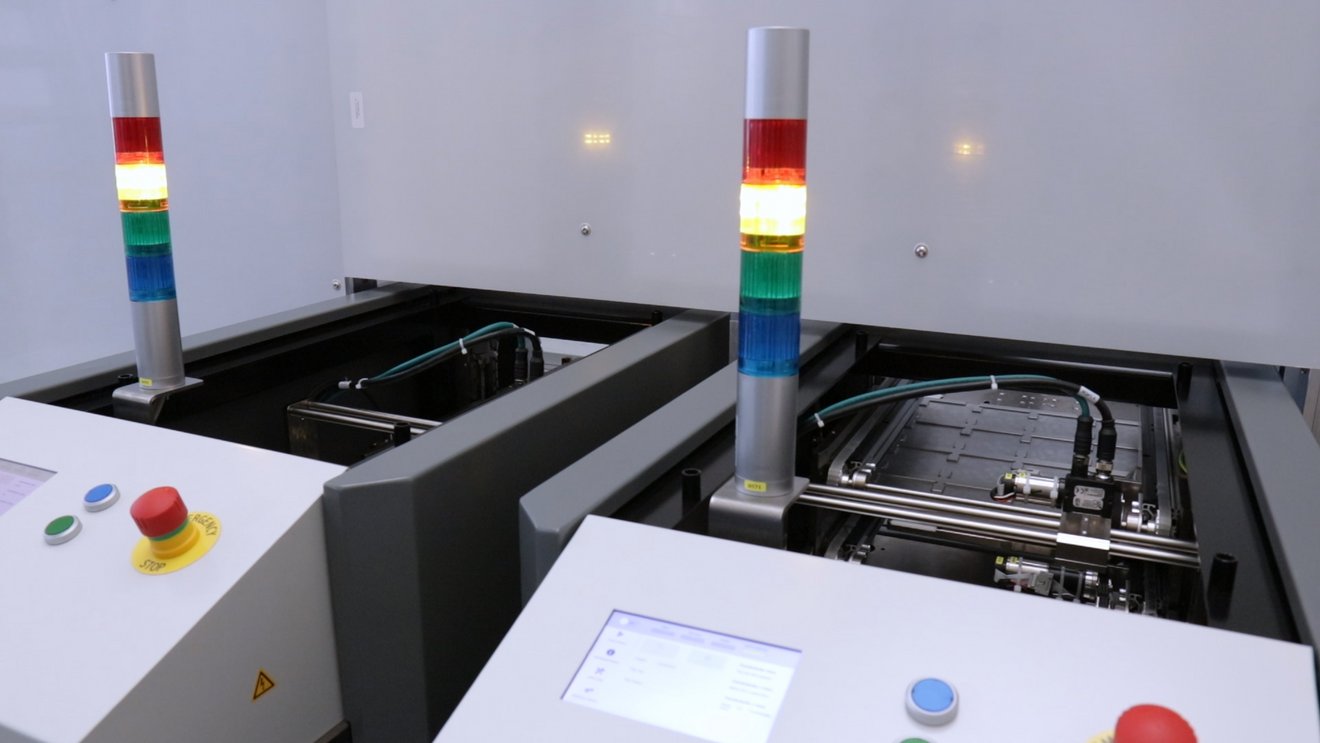

- Manual I/O ports (rotary gate)

- Automatic I/O ports (OHT connection)

- Connection to equipment possible

- SEMI-E88 MCS interface

- SEMI-E84 transfer interface

Technical data

- Average cycle time 22 s

- Dimensions:

- Length [Max.]: 7,8 m

- Width: 1,4 - 2,66 m (depends on carrier type)

- Height: 6 m (custom adjusted heights possible)

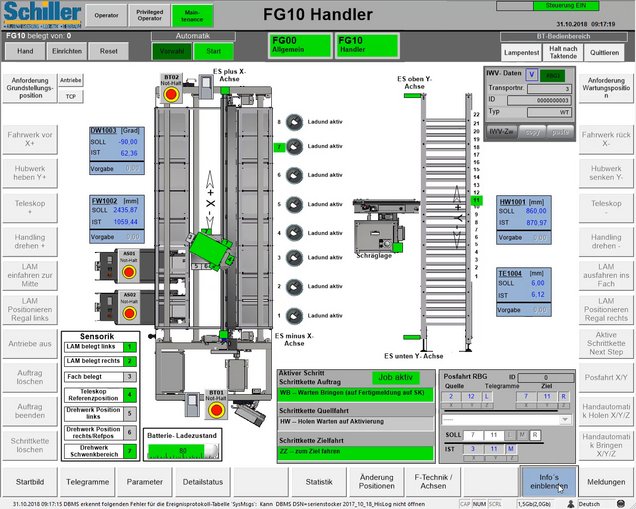

- SIEMENS S7 PLC

- HMI panel

Datasheet

Notice

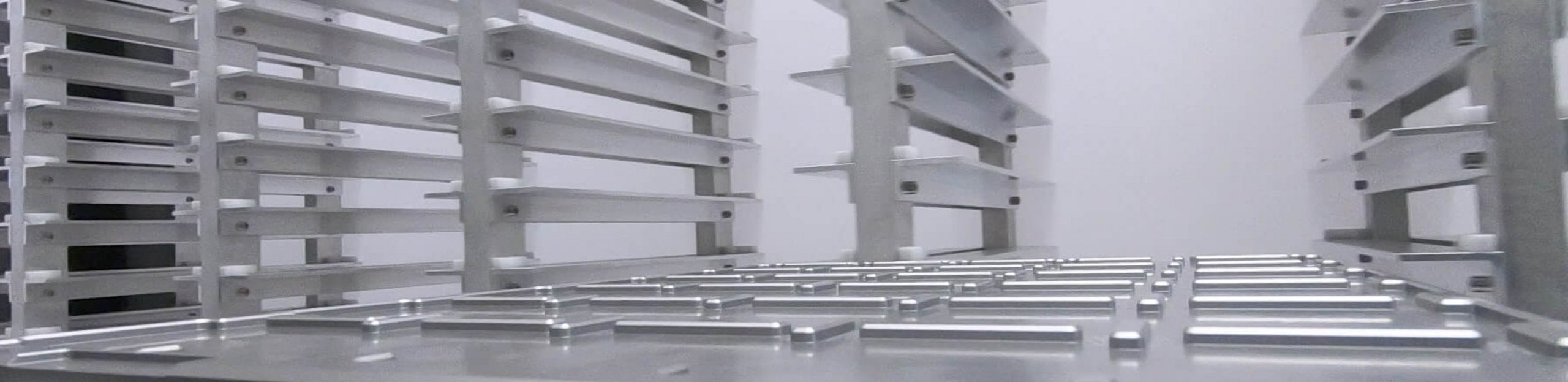

The Linear Stocker may be flexibly arranged for transport and storage of individual, customer-specific products, e.g. product carriers, 200/300mm cassettes and much more.

STORAGE OF PRODUCT CARRIERS

STORAGE OF CASSETTES

Software

Warehouse management system

Schiller SWarePro