Features

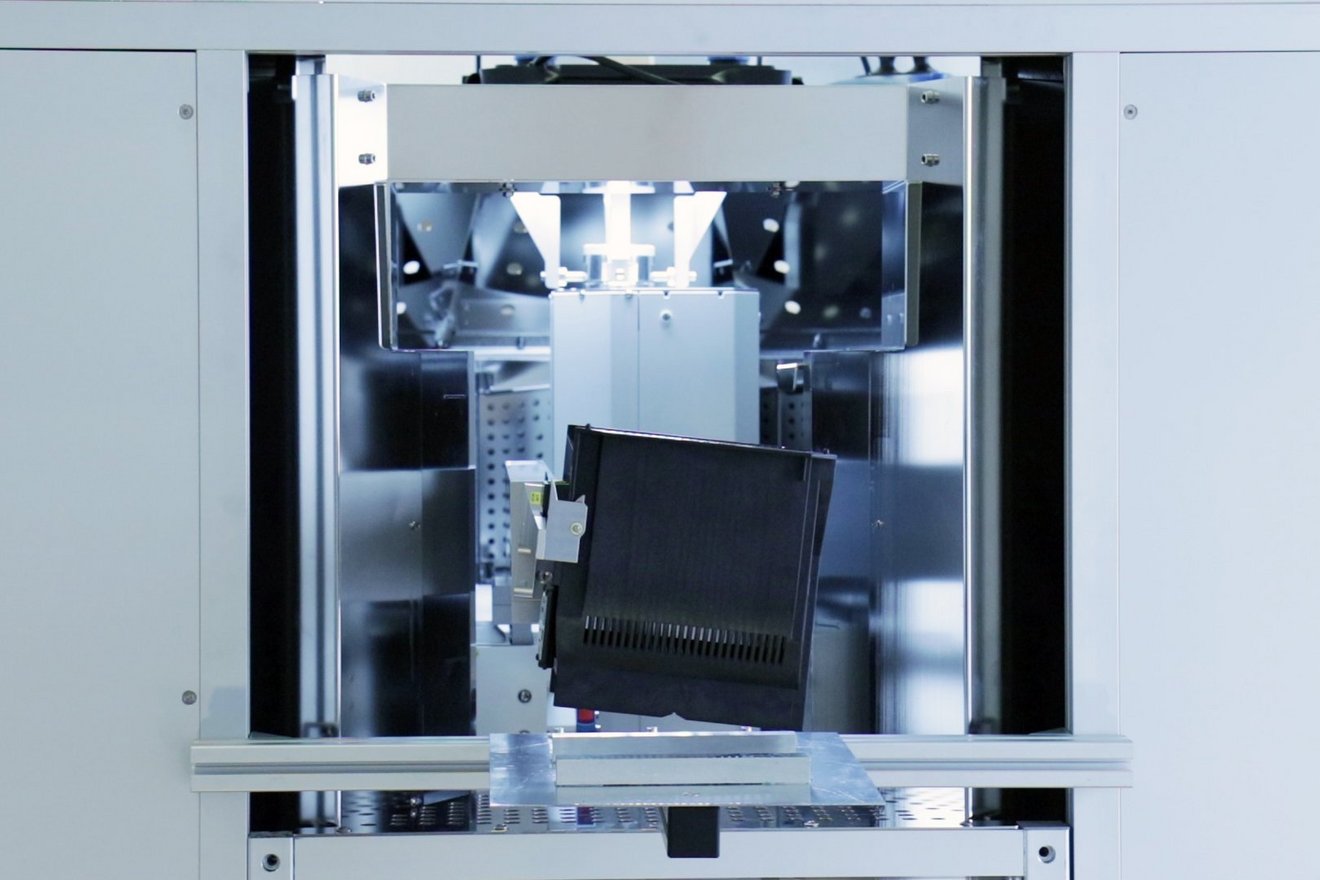

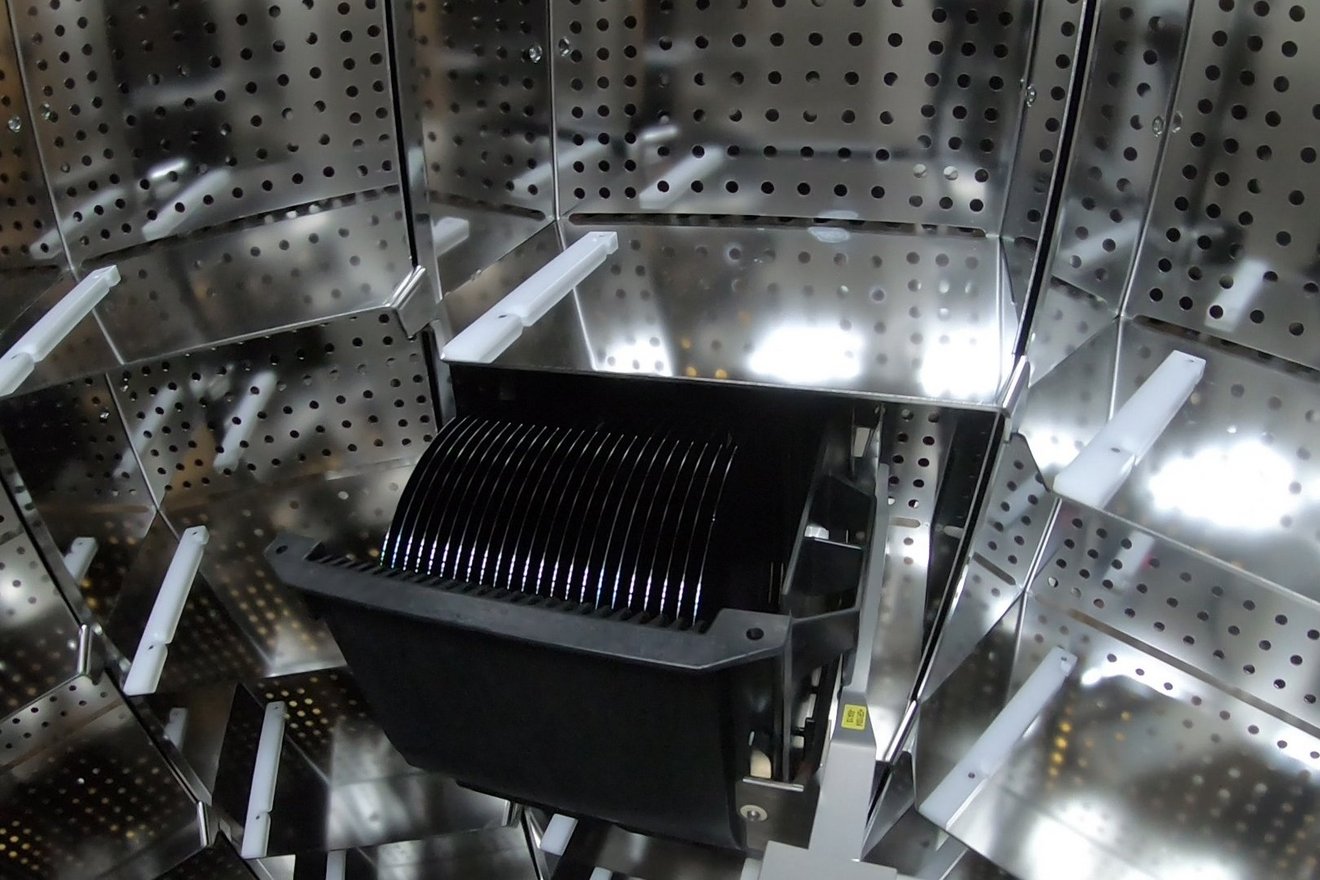

- Storage of different transport containers (Box HA200, OC)

- Fulfils ISO class 3 or 4 cleanroom class

- Storage and retrieval to external conveyor technology

- Manual and automatic I/O ports available

- SEMI-E88 MCS interface

- SEMI-E84 transfer interface

Technical data

- Average cycle time 28 - 32 sec.

- 11 storage spaces per lane

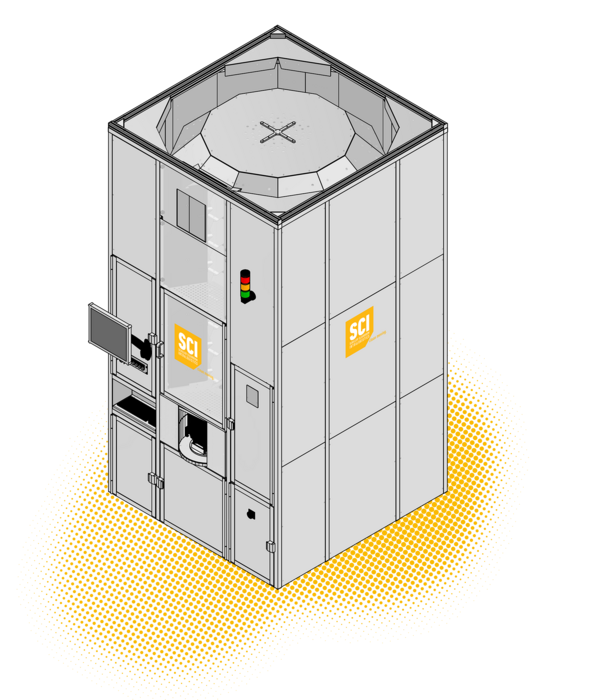

- High: variable between 7 and 12 lanes (2,8 m - 4,0 m)

- Outside dimensions: 1,8 m x 1,8 m base area

- All robotic axes are delivered with absolute value encoders combined with Faulhaber MC controllers

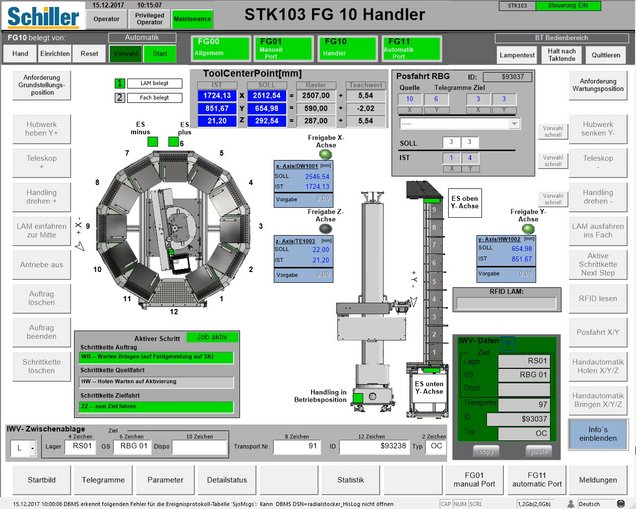

- SIEMENS S7 PLC

- Desktop-PC, Win10, 17‘‘ Panel

- PROGEA MOVICON high-end visualisation

Datasheet

Software

- Remote access: Web front-end including user administration

- Data tracking: Material tracking, system counter visualisation

- SECS interface: SEMI E88-conformant interface, expandable upon request by the customer

- Interfaces:

- Web frontend via http Port 80

- SECS/GEM Ethernet interface

- Ethernet interface to the PLC systems

- Inventory function

- Optional 3D inventory visualisation

Warehouse management system

Schiller SWarePro